There are some techniques used in tailoring that are rarely found in the pattern instructions. One of those is a chest piece, or chest shield.

There are some techniques used in tailoring that are rarely found in the pattern instructions. One of those is a chest piece, or chest shield.

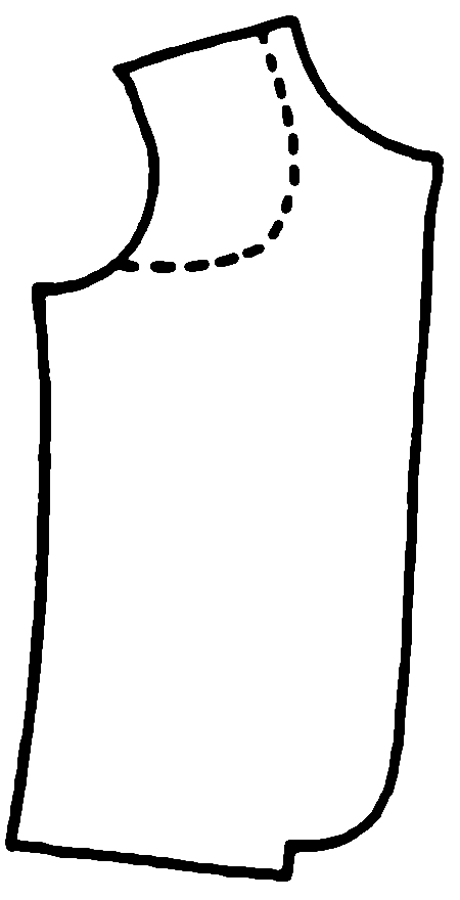

The chest shield is a layer — or, sometimes, multiple layers — that provide stability, body, and reinforcement to the upper front of a jacket. Every woman, even if large-busted, has a little crease or hollow next to the armhole in the chest area that can cause vertical wrinkles or folds in the upper chest of a jacket or coat. To remedy this, we put in a chest shield. The shield enhances the overall fit and appearance, and gives structure, support, and shape to the chest area. It also contributes to a more flattering and tailored look, creating a smooth and well-defined silhouette.

Although chest shields are common in men’s jackets and couture tailored garments, they are rarely seen in women’s ready-to-wear. Chest shields can be made from quality canvas, silk organza, batting, muslin, Pellon Fleece, or Thermolam. If more structure is needed, they can be multi-layered and any combination of the above.

TIP: Do not use fusible fleece as this is a high stress area on the garment and it will not stay fused.

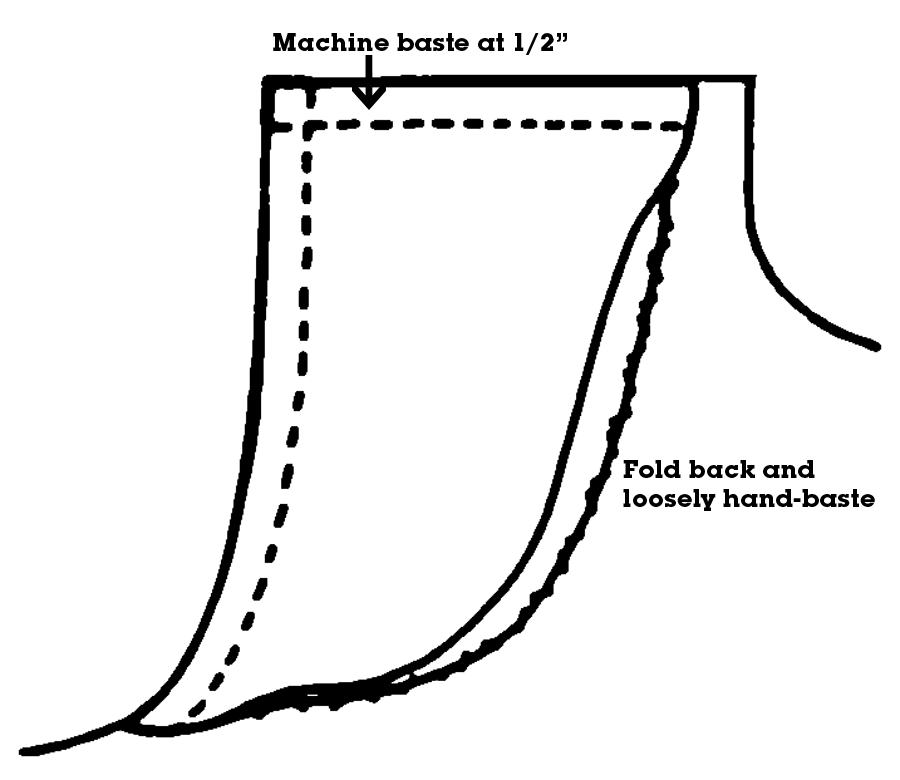

After you have applied interfacing to the jacket fronts, pin the chest pieces along the shoulder and armhole seams and baste them in place. Fold the curved edge back about 1/2″ and tack the chest piece to the jacket with a very loose running stitch, checking to be sure it does not show on the right side of the garment (Figure 2).

Sew the chest piece right into the shoulder and armhole seams during construction and trim the excess seam allowance from the chest pieces to reduce bulk. If your garment will be lined, the chest piece will go between the outer fabric and the inner lining.

Press the chest area over a ham and allow the garment to cool and dry in that position. The ham simulates the curves of the body and will help to shape the garment to your figure.