I love to do embroidery and when I work with cotton fabrics, I always starch them well before hooping. The starch makes the fabric crisp and the embroidery clean. After stitching, I then press again—without starch. After pressing a couple of the quilt blocks, I noticed some wrinkles along the stitching lines that I hadn’t noticed before. I pressed the second block and the same thing occurred. So, I starched the fabric again for the next block, stitched it, pressed and the same thing—only not quite as bad. This was perplexing so I began to do some investigating. I finally discovered that the poly mesh stabilizer I was using was SHRINKING when it was being pressed! It wasn’t a lot—about ¼” all around— but was enough to distort the embroidery and make me very unhappy.

My shrinking poly mesh stabilizer

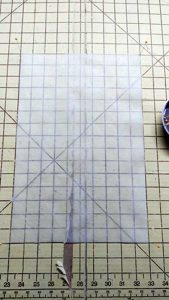

Here I cut the piece of poly mesh stabilizer, placed it on a cutting board and placed pins at the corners so you can see the original size.

I then took the piece of stabilizer to the ironing board and pressed it well (I used lots of steam, too) leaving the pins in the board so I could check the size after pressing.

The piece was flipped and pressed again. Now I must admit, I press with a hotter iron than most folks to do because I work very quickly and I work with a professional iron—but, I also tested with a household iron and basically got the same results. I pressed well in all directions and all over the stabilizer.

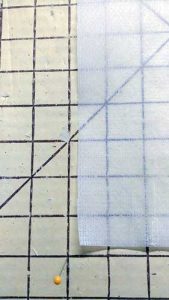

After the pressing, I let the stabilizer cool off and then I placed it back on the cutting surface, aligning the top and right sides to the original lines.

You can see how much this piece of stabilizer shrunk—it is enough to make a difference in the finished piece of embroidery.

If you find your pieces have wrinkles around the outer (and even sometimes inner) edges of your work, check your stabilizer by pre-shrinking it. I’ve been using this same stabilizer for years and had not had this problem before so I wonder if the production of the stabilizer has changed in some way—either the brand changed manufacturers or perhaps changed the fiber content in some manner (maybe less expensive fibers to make more profit to cut production costs?) I’ll never know unless I write to the manufacturer and chances are they will not tell me anything.

So, now every time I get a new bolt of stabilizer—any kind of stabilizer (except water soluble, of course) — I will be heat testing it to be sure it can hold up to washing and drying and pressing.

Sew ‘til next time, enjoy the journey of sewing!

~Ramona