We’ve received a lot of needle-related questions lately, so let’s get some answers.

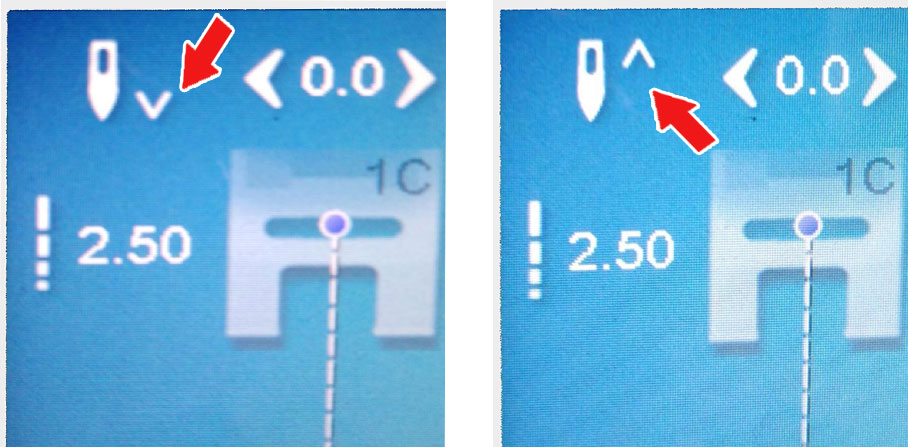

Q: My sewing machine has a needle-up/needle-down function. Why do I need that?

A: The needle positioning option eliminates the need to turn the machine hand-wheel manually to get the needle where you want it to be—either above the fabric level, or piercing the fabric under the presser foot.

The needle-down position is a favorite of quilters allowing an easier time with sewing curves and pivoting at corners. With the needle down, it’s easy to lift the presser foot to adjust the position of the fabric as the needle keeps the fabric from moving or sliding while you’re making adjustments. It’s also helpful if you’re dealing with large, bulky items like quilts, as again it holds the fabric in place for you.

The needle-up position is handy for beginning and end a seam so you’re sure the needle is at its highest point and thread take-up level is as high as it will go, signaling that the stitch cycle is complete. It also allows you to use a thread cutter if your machine has one, without interference from the needle.

Many machines with the needle-up/needle-down function allow you to tap the foot pedal once to change the needle placement. For example, if you have the machine set to needle down and you want it up, simply tap the foot pedal and it will raise.

This function is not a necessity, as you can always move the hand-wheel to adjust the needle position, but it’s a handy feature if you do have it.

Q: What is a titanium needle and where should I use it?

A: A titanium needle shaft is coated with titanium nitride that resists adhesive found on embroidery stabilizers and it improves needle wear by making the needle about three times harder than the standard chrome versions. That increased strength makes these specialty needles ideal for sewing heavier fabrics like denim, as well as for stitching high-density embroidery designs. In addition to being stronger, a titanium needle also helps minimize thread breakage by deflecting the heat built up with fast sewing speeds (think embroidery, but also speedy sewing of seams). Titanium-coated needles last from five to eight times longer than non-coated needles. These needles are available from several companies and in several styles of needle points and sizes; some brands refer to them simply as “gold needles” due to their coloring.

Q: How often should I change my sewing machine needle?

A: This is probably the most frequently asked sewing question ever! Answers vary depending on who you ask, but the constant among them is that if the machine isn’t stitching properly, change the needle. When you think about how many times the needle penetrates the fabric you’re sewing a single project, it’s easy for the tip to become dull (especially when sewing on synthetic fibers), or damaged (especially if you sew over pins). If your machine stitches louder than normal, it could be a dull needle. If it doesn’t form stitches properly, it could be a damaged needle.

Damaged or bent needles can not only damage your machine, but also make tears or snags in your fabric. Obviously, if a needle breaks, you’ll need to replace it, but don’t necessarily wait for that travesty, as your fabric could be damaged by then.

Some experts recommend changing your needle with every sewing project just to be sure, or for every five to six sewing hours. If you don’t subscribe to that theory, then keep a watchful eye on the stitch quality and the sound of the stitching.

As important as it is to change the needle regularly, it’s equally important to choose the right type of needle for the fabric you’re sewing and the function you’re doing. Some needles are keyed to fabrics—like Jersey, Stretch and Denim options, while others are keyed to the function, like Embroidery, Quilting and Appliqué.

Q: Can my machine use a twin needle?

A: With the exception of a straight-stitch-only machine, most can use a twin needle. If your machine has a zigzag needle hole, yes you can. But, double check your owner’s manual to be sure. Twin needles come in various types and width spacing, and some machines may have limitations of one or both of those factors.

Twin needles are used to sew two rows of stitching exactly parallel to each other, and they couple two separate needles onto a single shank that’s inserted into the machine as if it were one needle. The bobbin picks up both threads and forms a zigzag on the underside of the stitching. They can be used with straight or limited-width decorative stitches.

~Linda Griepentrog is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and three dogs, Yohnuh, Abby, and Lizzie. Contact her at .